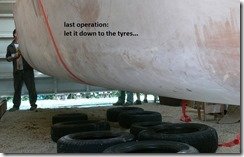

Turning the hull

Fairing after 3nd layer of coating epoxy

This is the last layer under the paint. Anyway, the painting base coating will be also epoxy, and the middle layers – the so-called ‘undercoat’ as well.

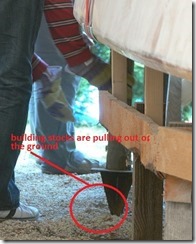

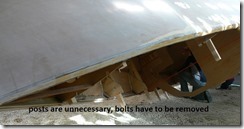

Preparation for turning the hull (if you can, do all the painting before turning the hull, later much more difficult to paint)

Fairing after 2nd layer of high coat

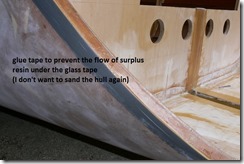

Putting on the second layer of UV Epoxy was relatively easy, but after each layer, I needed to sand the surface. Sanding is quite hard work, but the surface is getting nicer and nicer after every hour of the fairing. Some pictures: during the sanding process…

3rd layer of epoxy over glass cloth

It took approximately 3 hours to coat the first layer of UV “resistant” epoxy resin above the glass cloth. The resin: SR 5550 – SD 5504.

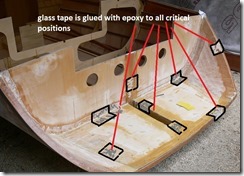

Fiberglass reinforcements

Before the high coating I reinforced the hull with 194 g/m2 2/2 fiberglass cloth. It was not necessary according to the plan – I just wanted to achieve more strength and thickness. Be sure that enough resin covers the fiber glass. I used the next method: first I covered the hull with low density epoxy resin before spreading the glass cloth. Just right after this, I covered the glass cloth onto the resin-wet surface without a pucker. After covering the glass, I lubricated the top of the glass coat with resin using a painting roll and plastic spatula. Very important to avoid the air bubbles under the glass. It needs pretty much force, but be careful not to make the coat ropy.